Why is the soil a decisive factor in foundation construction?

Why is the soil a decisive factor in foundation construction?

Natural soils

Our prevalent soil type is known as natural soil. It’s usually made up of both organic and non-organic components. Organic soils are formed during the natural decomposition process. Humus, turf and moor-like soils fall into this category and usually have a high water content and low oxygen content. On the contrary, non-organic soil elements are rather water-permeable and rich in oxygen and are produced through rock weathering. These include gravel and small-grain sand, as well as limestone, gypsum and clay. If there is a mixture of sand, clay and silt this is known as loam. If you mix clay and limestone, you get marl. Natural soils can consist of a mixture of these components, either accumulated naturally or having been poured. Whether a natural soil is capable of bearing a load or not depends on its mixture ratio and on the thickness of the bedding.

Evaluation of the load-bearing capacity

When it comes to the load-bearing capacity of the soil, it is important to differentiate between cohesive and non-cohesive soils. Cohesive soils primarily consist of loam, silt, clay or limestone. A characteristic of cohesive soils is that they are capable of absorbing large quantities of water which, when combined with the tendency of individual particles to adhere to each other, often results in the soil turning into mud. A state that significantly reduces the soil’s load-bearing capacity and therefore makes it unsuitable for construction. However, when they are dry cohesive soils can have an excellent load-bearing capacity. On the other hand, when non-cohesive soils are packed tightly they have an extremely high load-bearing capacity. In general, they consist of sandy and gravelly components and are permeable to water and air. In between these two categories there is also weakly-cohesive soil, which is more or less a combination of the two other soil types. Alongside the load-bearing capacity, the corrosivity of the soil also plays an important role.

Corrosion is not to be underestimated.

By corrosion, we mean the decomposition of a substance caused by reaction with its surroundings. This could be, for example, the effect of water on rocks or as a chemical reaction when occurring on metals. As such, corrosion always plays a role when it comes to construction projects, as soil is a medium that can cause corrosion because of what it contains. However, this depends on its composition. For this reason, soil is split into different classes with different levels of corrosive behaviour or aggressiveness. The classes are defined based on the oxygen content, water absorption capacity or soil resistance. Barely aggressive types of soil can be found in Soil Class I. Usually, they are non-cohesive soils containing sand and gravel. Cohesive soils, like marl and loam, mostly fall under the slightly aggressive category, Soil Class II. All highly aggressive soils fall under Soil Class III. These are usually organic soils like humus, turf or moor soils. But this class also includes polluted soils and former landfill sites. In Europe, soils primarily fall into Soil Classes I and II.

The perfect subsoil

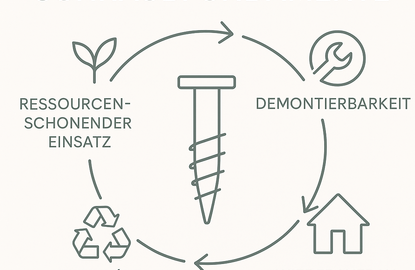

Is there really such a thing as the perfect subsoil? From what you have previously read in this article, you can come to the conclusion that non-cohesive, class I soils are the best type of subsoil for construction. However, as soils can always have different mixture ratios and soil classes are not really that exact, the construction subsoil must always be examined and evaluated individually. This can only be done with a soil survey. You can then choose what type of foundation to use according to the composition of the soil layers. This could be a classic concrete foundation or an innovative, concrete-free alternative like KRINNER ground screws.

Ground screws can be used almost anywhere

In principle, KRINNER ground screws can be used in almost all types of soil, depending on the soil composition. Our ground screws are galvanised steel components which can be driven into the ground with the aid of a ground screw driver. The foundation gets its stability and load-bearing capacity from the driving in pressure and lateral pressure from the soil. Hence, they can carry the same load as conventional concrete foundations. KRINNER ground screws are particularly suitable for use on construction site where the load-bearing soil can only be found in the deeper soil layers. This is where the extendible V-series screws from KRINNER have a clear advantage over traditional concrete foundations.

![[Translate to en:] [Translate to en:]](/fileadmin/_processed_/1/7/csm_Bild_2003416679.jpg)

![[Translate to en:] [Translate to en:]](/fileadmin/_processed_/2/e/csm_MSG-Signet-Schwarz_ef33dcaf08.png)

![[Translate to en:] [Translate to en:]](/fileadmin/_processed_/4/5/csm_TERR_TM_V_CMYK_FC_Pos_5304b559c9.jpg)