Sustainable PV modules on KRINNER Ground Screws

Sustainable PV modules on KRINNER Ground Screws

Company Altec also uses KRINNER Ground Screws for its PV table constructions:

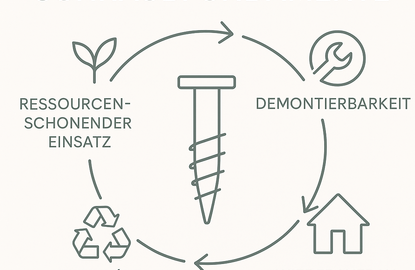

The frame is largely made of aluminum and consists of a stable construction of transverse and longitudinal connections. Thanks to this ingenious structure, no elaborate foundations are required: It is erected quite simply using a KRINNER manual lathe without the need for excavators or earthmoving. This machine can also be ordered for hire. The use of KRINNER screws means that surfaces are not sealed and the soil ecosystem remains untouched. Rainwater can seep away and damage to the ground is avoided.

KRINNER ground screws are suitable for almost all types of soil. If required, a KRINNER tension and compression test device can be borrowed to ensure suitability for use in the existing soil. Only two tools are required to assemble the frame. You can choose between inclination angles of 15°, 20° and 25°. The outdoor table consists of two rows of nine modules each. It is installed vertically, i.e. the modules are clamped on the long side. Any number of outdoor tables can be installed next to or behind each other.

Advantages:

- Simple installation thanks to KRINNER Ground Screws

- Only minimal earthworks without high voltage current

- Can be installed with hand tools - no large-scale equipment (excavator) required

- Height compensation possible thanks to individually shortenable supports

- Complete system, no planning costs

Requirements:

The maximum module width is 1135 mm, the maximum module length 2000 mm. The system is delivered with KRINNER Ground Screws with a length of 1300 mm. A rental machine for the installation can be provided. A standard household 230 V connection is required for this. Structural verification for snow loads up to 2.17 kN/m² and wind loads up to 0.71 kN/m² is available.

Interested?

Interested?

Do you have a project that you think would benefit from KRINNER ground screws?

![[Translate to en:] [Translate to en:]](/fileadmin/_processed_/1/7/csm_Bild_2003416679.jpg)

![[Translate to en:] [Translate to en:]](/fileadmin/_processed_/2/e/csm_MSG-Signet-Schwarz_ef33dcaf08.png)

![[Translate to en:] [Translate to en:]](/fileadmin/_processed_/4/5/csm_TERR_TM_V_CMYK_FC_Pos_5304b559c9.jpg)